Who we are

About Us

Mansfields is a privately owned Australian company with over 50 years’ experience, providing Dry Food Contract Manufacturing services to an extensive range of FMCG clients, including some of the largest local and international food companies operating in Australia.

Mansfields is nationally recognised as the leader in the Dry Food Contract Manufacturing industry. We have in place one of the Industry’s most well-developed and highly effective food safety and quality assurance programs including the latest ERP technology which gives our clients access to up to the minute, accurate and traceable information.

We also offer research and product development services to our clients and with our strong engineering department, we can tailor plant and equipment to suit specific customer requirements.

Health & Wellness Division

Branded Division

Mansfields Services

What we do is governed by modern technology, but as we have grown, our human values remain unchanged. We highly value integrity, honesty and fairness in all our undertakings. We are passionate about the service we deliver. We are a progressive and innovative company! We take pride in the high standards that we have established to maintain Mansfields’ name as the number one Dry Food Contract Manufacturer in Australia.

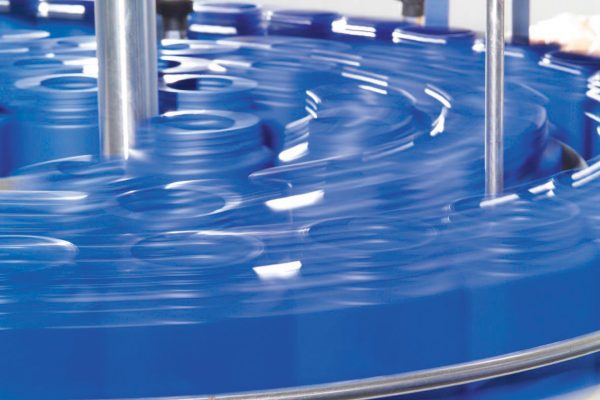

Blending

Sachets

Retail Display Cartons

Tubs

Cans / Canisters

P.E.T Bottles

Australian Owned

Mansfields have been Australian owned and operated since it opened its doors in November 1972. Owner Geoff Humbert and family have been running the business since 1986.

Innovation And Technology

Mansfields are committed to being at the forefront of technology and innovation. Our purpose built operational systems allow us to be more flexible and responsive to customer requirements.

R&D Solutions

Our experienced technical team ensures that the process from initial product development through to launch runs smoothly whilst liaising with you, the customer at every step.

Quality Certification

Mansfields has food safety and quality accreditations including AA Grade BRC, WQA, Coles, YUM and RSPO as well as many client specific accreditations. Our quality systems are tailored to the varying requirements of our many clients.

We Are Nationally Recognised As The Leader In The Dry Food Contract Manufacturing.

Mansfields packs a range of food items into various packaging formats on a number of high speed automated lines. Packaging Formats such as Composite/Steel cans, Canisters and P.E.T. bottles can be used with alternative lidding and insertion applications.

Our Partners

Why Choose Mansfields

At Mansfields quality is paramount as our reputation depends on it.

We are Industry Leaders

With over 10,000 square meters of manufacturing facility and 24 manufacturing lines we are the largest Dry Food Contract Manufacturer in Australia and with that size comes the speed and flexibility that today’s market demands! Our quality processes and attention to detail, ensures that every client’s product is treated as it is our own.

Focused on Getting Results

Mansfields are a result driven organisation – We are not satisfied with anything less than perfection in everything we do. We measure our performance and results at every stage of our manufacturing process. We will work with you to research and implement solutions to meet your needs and will do so with passion and integrity.

Client Collaboration

From the first phone call to the last product out the door, we are with our clients every step of the way, sharing our forty years of food manufacturing experience to ensure that your product arrives on shelf, on time and in full for the most cost competitive price. Mansfields are as passionate about your brand’s success as you are!

Our Capabilities

We will work with you to research and implement solutions to meet your needs and will do so with passion and integrity

A FLEXIBLE EXTERNAL MANUFACTURING PARTNER

With over 50 years of experience in Dry Food manufacturing, we have worked with some of the largest food manufacturers and retailers to bring their products to market quickly and safely. Whether you are looking for an “off the shelf” product solution or have your own formulation we can help you bring your idea to market.

STRINGENT QUALITY PROCEDURES AND CONTROL

Mansfield’s customers feel secure knowing that our production facility is always audit ready. They know we can meet tough certification requirements and that our sole purpose lies in manufacturing their products with strict quality and confidentiality controls.

AWARD WINNING ERP TECHNOLOGY

Mansfield’s customised ERP system gives our customers direct access to accurate and immediate production information which is an important component of our customers’ Quality Systems requirements. Our customers’ auditors have praised the level of detail and the high level of traceability offered by the new ERP system.

FLEXIBLE PACKAGING OPTIONS

You can specify nearly any type of food packaging format when you outsource dry food production through Mansfields. Packaging design is also a key function of our business and we can advise you on what is the best packaging vehicle for your product.

LATEST TECHNOLOGY IN AUTOMATED MACHINERY

Mansfields have researched and invested in the most advanced machinery available in the world today to enable us to copack a vast array of packaging components from large scale bagging units to cartoning and customer specific lines. At the same time we have the technical expertise and engineering ability to design and create highly efficient and cost effective packaging lines ourselves to customise and cater for specific customer requirements.

BAG IN BOX SPECIALISTS

We pride ourselves on our ability to make products for our customer’s retail success. With state of the art equipment, Mansfields offer a range of bag in box solutions for dried food manufacture.

WAREHOUSING & LOGISTICS

Our warehousing is designed to plan and store materials for on demand production and manufacturing. Each warehouse location is designated and labelled for identification and tracking. Raw materials are housed separately away from packaging and finished goods with each area utilizing dedicated personnel and careful segregation of allergens. Mansfield’s believes in constant refinement and improvement of our facilities and services to better serve our customers. Our warehousing and logistics capabilities demonstrate this commitment as an extension of services designed to make your operations more efficient, effective and profitable.

FULL SERVICE MANUFACTURING

Mansfields are a full service manufacturing provider for Dry Food production. Our team operates in a 10,000 square metre production facility that provides a full range of services from concept through Research & Development, Manufacturing, Blending and Instantizing to packaging in a wide variety of formats.

Decision for Nature

Agroly News

Agroly is a global community of practice that facilitates dialogue, information exchange and

use of information and communication technologies.

Introducing Mansfields’ New Packaging Format: Stick Sachets

At Mansfields, we are committed to innovation and meeting the ever-evolving needs of our customers. We are excited to announce the launch of our latest packaging format: stick sachets! Why Stick Sachets? Stick sachets are a versatile and convenient...

Mitchell Humbert

07/25/2024

Project Selection

Criteria Process

Our 5 Step Project Selection Criteria Process allows you, the prospective customer and Mansfields to collect and understand the information that is needed to scope your project in order to get the most optimal outcome.

-

Step 1. Planning

What Ingredients are required?

-Can the Customer provide the correct

-Terminology for the Ingredients required?

-Does the Customer require Mansfields to source the Ingredients and if so, in what Format & Quantity?

-Can the Customer provide Samples of the Food Ingredients required?

-Can the Customer provide Samples of the required finished Product -

Step 2. Food Safety

What Ingredients are required?

-Can the Customer provide the correct

-Terminology for the Ingredients required?

-Does the Customer require Mansfields to source the Ingredients and if so, in what Format & Quantity?

-Can the Customer provide Samples of the Food Ingredients required?

-Can the Customer provide Samples of the required finished Product -

Step 3. Packaging

What Ingredients are required?

-Can the Customer provide the correct

-Terminology for the Ingredients required?

-Does the Customer require Mansfields to source the Ingredients and if so, in what Format & Quantity?

-Can the Customer provide Samples of the Food Ingredients required?

-Can the Customer provide Samples of the required finished Product -

Step 4. Production

What Ingredients are required?

-Can the Customer provide the correct

-Terminology for the Ingredients required?

-Does the Customer require Mansfields to source the Ingredients and if so, in what Format & Quantity?

-Can the Customer provide Samples of the Food Ingredients required?

-Can the Customer provide Samples of the required finished Product -

Step 5. Logistics

What Ingredients are required?

-Can the Customer provide the correct

-Terminology for the Ingredients required?

-Does the Customer require Mansfields to source the Ingredients and if so, in what Format & Quantity?

-Can the Customer provide Samples of the Food Ingredients required?

-Can the Customer provide Samples of the required finished Product

We Love

people says

We specialise in intelligent & effective Search and believes in the power of partnerships to grow business. We use agronomic machine learning, remote sensing.

Finding the right financial lender is extremely important. In the late I operated a third generation dairy on around three hundred acres of land.

Jaret Smith

Web Designer

What other industry has as large of an impact on the world as agriculture. You look at this corn and, to the average person, they see this as just a corn field. They don’t see.

Laura Thomas

Marketing

Most of the corn crops like these are used as the main energy ingredient in livestock feed. Corn is also processed into a multitude of food and industrial products.

Matt Cimino

Senior Lawyer

When we needed to take our farm to the next level, we wanted to work with people who truly know the farm and agriculture business.

Melissa Jones

Accounter

Most of the corn crops like these are used as the main energy ingredient in livestock feed. Corn is also processed into a multitude of food and industrial products.

Adriana Porter

Web Designer

Most of the corn crops like these are used as the main energy ingredient in livestock feed. Corn is also processed into a multitude of food and industrial products.

John Doe

Web Designer

Most of the corn crops like these are used as the main energy ingredient in livestock feed. Corn is also processed into a multitude of food and industrial products.

Martha Smith

Web Developer

Our Head Office

13-17 Fiveways Boulevard

KEYSBOROUGH VIC 3173

Australia

Call Us

+61 3 9701 8711

Mon - Fri 9am - 5pm

Email Us

The Spirit

of Innovation

If you are looking for a fun, challenging, fast-paced work environment with growth opportunities, come join our incredible.